Email us

coco20.xu@gmail.comContact Number

/In the sophisticated world of electronic manufacturing, the "nervous system" of any device—the data cable assembly—often determines the success or failure of the entire project. As data transmission speeds increase and industrial environments become more electrically "noisy," a simple off-the-shelf cable is no longer sufficient.

Drawing on Eweulwire’s 28 years of specialized manufacturing experience since 1997.Over the decades, we have transitioned from simple ribbon cables to complex, high-speed multi-core assemblies. This longevity has allowed us to accumulate a proprietary database of material performance—understanding exactly how different PVC jackets react to industrial lubricants or how specific braiding angles affect signal skew in high-frequency applicationsthis guide explores the critical engineering behind data connectivity. We will break down why material selection and shielding protocols are the true differentiators between a consumer-grade wire and a mission-critical industrial component.

A data cable assembly is a precision-engineered system. While many suppliers focus on cost, Eweulwire’s engineering team prioritizes signal integrity through three foundational pillars:

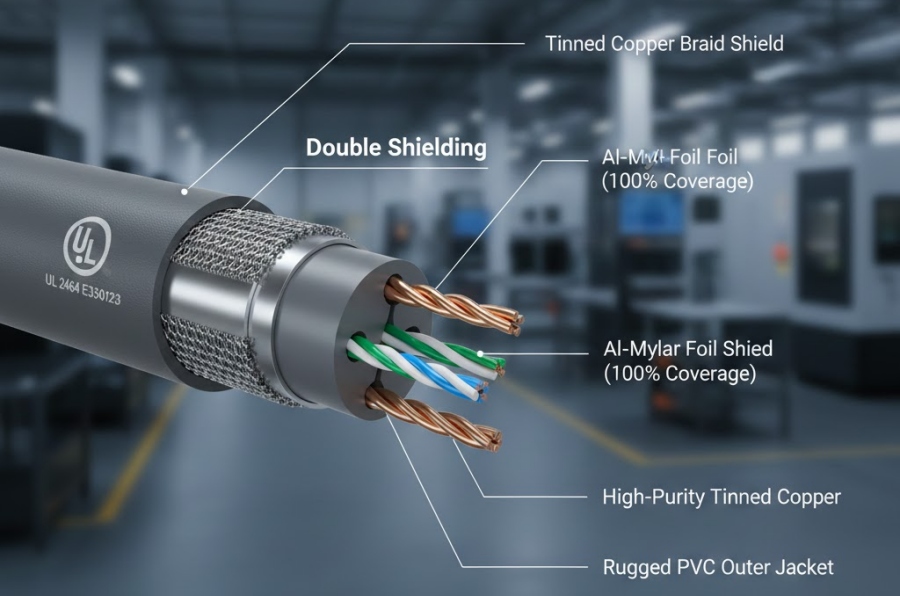

At the heart of every high-speed data cable is the conductor. In our Shenzhen facility, we exclusively use high-purity tinned copper or bare copper. Tinned copper, in particular, is essential for industrial signal cables exposed to moisture, as it prevents the oxidation that leads to signal attenuation over time. This is a standard we have maintained since our founding to ensure product lifespans of 10-20 years in the field.

Technical Insight: While many factories opt for copper-clad aluminum (CCA) to reduce costs, we maintain a strict 100% pure copper policy. During our 28 years of manufacturing, we have found that CCA simply cannot provide the mechanical strength required for dynamic industrial applications, leading to brittle fractures and intermittent signal failure. By utilizing tinned copper, we also facilitate superior solderability at the termination points, which is a critical failure zone in complex harnesses.

In an industrial plant or a medical imaging suite, electromagnetic interference (EMI) is constant. To combat this, we utilize a "Double Shielding" approach:

Data loss often occurs at the termination point. By using custom-designed molds for USB and LVDS connectors, we ensure that the internal solder joints are protected from mechanical stress and vibration, a requirement we strictly enforce for our IATF 16949 automotive-grade clients.

The term "data cable" covers a vast spectrum. Understanding where your project fits on this spectrum is the first step toward successful procurement.

Most people associate USB with consumer electronics, but in a B2B context, USB 2.0/3.0/4.0 assemblies must be ruggedized. Eweulwire’s industrial USB solutions feature reinforced jackets and gold-plated contacts to ensure stable data rates even in environments with constant vibration.

Low-Voltage Differential Signaling (LVDS) is critical for medical displays and industrial HMI (Human-Machine Interface) panels. Because these cables transmit high volumes of data at low voltages, the twisting pitch of the pairs must be exact. Our automated production lines in Shenzhen are calibrated to maintain these tolerances, ensuring zero packet loss during transmission.

To achieve the precision required for zero-packet-loss LVDS assemblies, Eweulwire utilizes advanced laser micrometer systems on our production lines. This allows us to monitor the twisting pitch of pairs in real-time. Even a 0.5mm variance in pitch can disrupt impedance matching (±5Ω), which is why our automated calibration is non-negotiable for high-end display panels.

These are the workhorses of automation. Often used in PLC (Programmable Logic Controller) systems, these cables must be resistant to oil, chemicals, and abrasion. We leverage our UL-certified material library (such as UL 2464) to provide jackets that can withstand the rigors of a 24/7 factory floor.

A common pitfall for procurement managers is relying solely on a supplier's certificate. At Eweulwire, we believe authority is earned through transparency.

We always advise our partners to verify UL File Numbers on the official UL Product iQ™ database. Transparency in certification is the only way to guarantee that the VW-1 flame resistance and electrical ratings promised are actually delivered.

We don't just trust raw material certificates; we verify copper purity and insulation thickness in-house.

Every data assembly undergoes automated continuity, high-voltage insulation, and pull-force testing.

This rigorous process is why global leaders in the medical and automotive sectors have trusted our factory since 1997.

This "double-lock" verification—checking both the raw material and the finished assembly—is a core component of our IATF 16949 compliance. Since obtaining our UL certification in 2012, we have processed over 5,000 unique technical drawings, each subject to this same rigorous testing protocol to ensure that what leaves our Shenzhen factory performs flawlessly in the field.

|

Application Category |

Cable Type |

Key Performance Metric |

Eweulwire Advantage |

|

Industrial Automation |

UL 2464 / Signal Cable |

Oil & Abrasion Resistance |

28 Years of Durability Data |

|

High-End Displays |

LVDS / Micro-Coaxial |

Impedance Matching (±5Ω) |

Precision Automated Assembly |

|

Medical Diagnostics |

Custom Shielded Multi-Core |

Low-Noise / Biocompatibility |

Clean Production Environment |

|

Power & Data |

Hybrid USB/Power Cables |

Current Carrying Capacity |

IATF 16949 Certified Quality |

Investing in high-quality data cable assemblies is an investment in your brand’s reputation. Whether you need a standard USB interface or a highly complex, shielded industrial signal harness, the manufacturing partner you choose must offer more than just a product—they must offer technical expertise and proven reliability.

As a UL-certified manufacturer since 2012 with deep roots in the Shenzhen manufacturing hub, Eweulwire is ready to transform your technical drawings into high-performance connectivity solutions.

Ready to discuss your custom data cable requirements? Contact Eweulwire Today for a technical consultation with our senior engineering team.