Automobile

Automobile

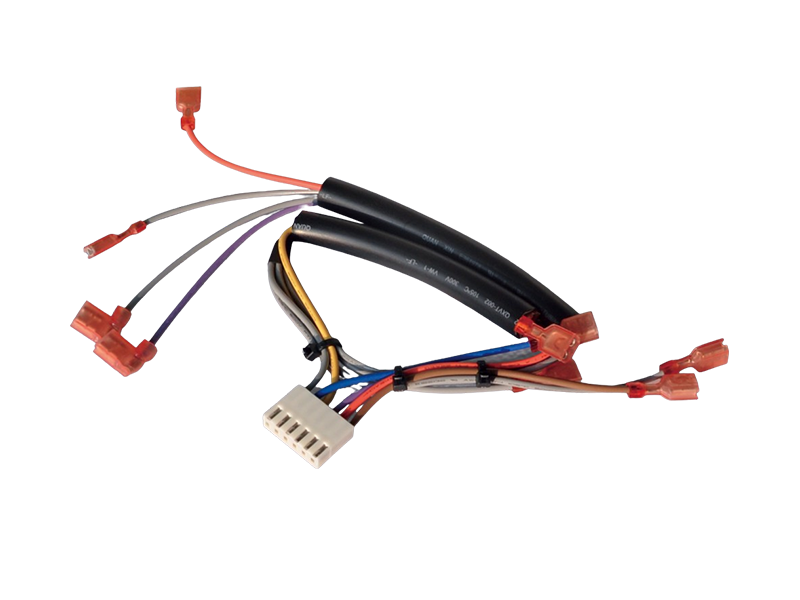

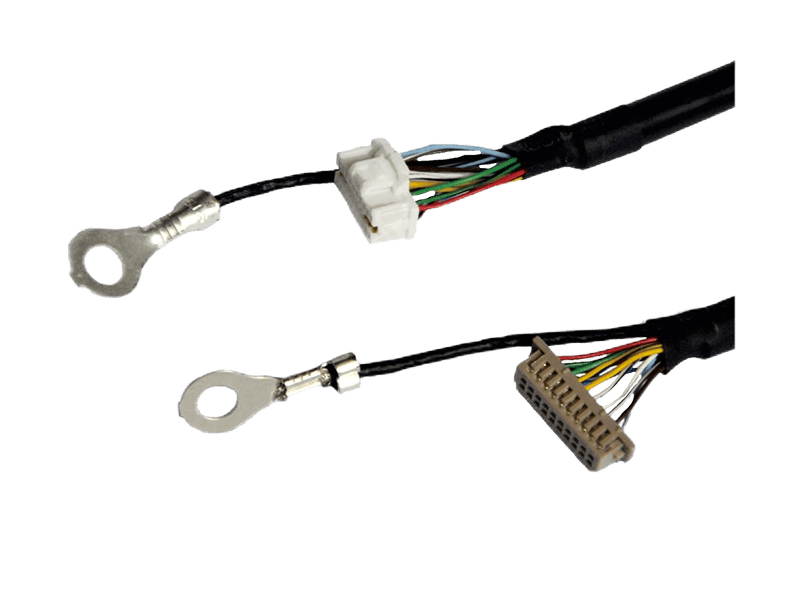

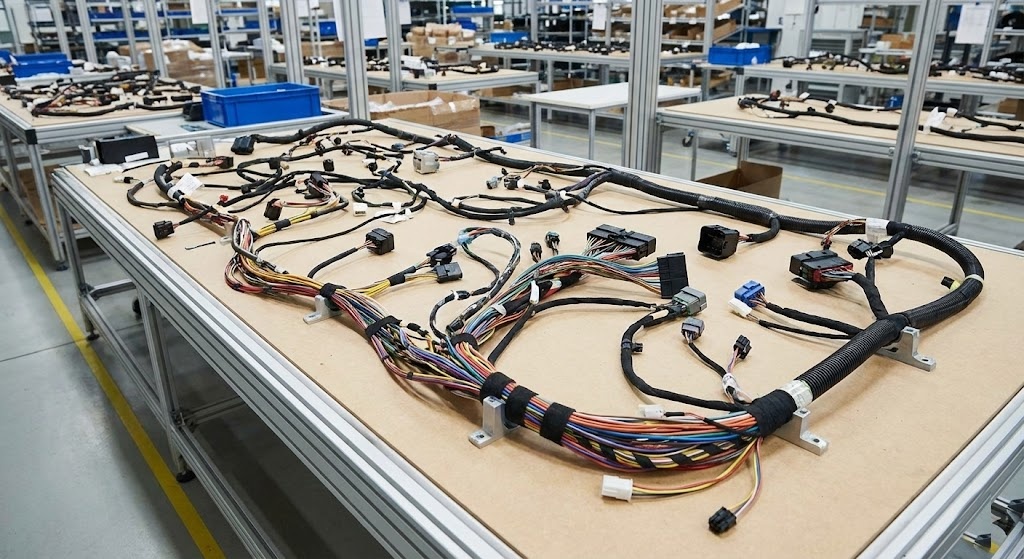

Applications of Terminal Wires in the Automotive Field

Engine Control System

Terminal wires are used to connect the Engine Control Unit (ECU) with various sensors and actuators. For example, the terminal wire connecting the crankshaft position sensor to the ECU is made of heat-resistant and corrosion-resistant materials. It can operate stably in the high-temperature and high-vibration environment of the engine compartment, accurately transmitting the engine speed and crankshaft position signals to the ECU. The ECU then precisely controls the fuel injection time and ignition timing based on these signals to ensure the efficient operation of the engine and good fuel economy.

The terminal wire connecting the air-flow sensor to the ECU is responsible for transmitting the air-flow signal to the ECU. The ECU calculates the fuel injection quantity based on this signal and other sensor signals to achieve optimal air-fuel ratio control.

The knock sensor is connected to the ECU via a terminal wire. When engine knock occurs, the knock sensor generates a signal, which is transmitted to the ECU through the terminal wire. The ECU then promptly adjusts parameters such as the ignition advance angle to prevent engine damage.

In-Vehicle Entertainment System

The flat cable connecting the in-vehicle display screen to the host is compact in size, facilitating wiring in the limited space inside the vehicle. It has excellent signal transmission performance and can stably transmit high-definition video signals, providing drivers and passengers with a clear visual experience.

The audio cable connecting the audio system is made of high-fidelity materials, which can effectively reduce audio signal distortion and restore high-quality music effects, bringing a superior auditory experience to vehicle occupants.

The navigation module is connected to the display screen and the host through terminal wires, enabling the transmission and display of navigation data, providing drivers with accurate navigation information.

Safety System

In the Anti-Lock Braking System (ABS), the terminal wire connecting the wheel-speed sensor to the ABS control module can quickly transmit the wheel-speed signals monitored in real-time by the wheel-speed sensor to the ABS control module. The module determines whether the wheels are about to lock based on these signals and promptly adjusts the braking pressure to prevent the vehicle from losing control during braking and ensure driving safety.

In the airbag system, the terminal wire connecting the collision sensor to the airbag control unit is required to have extremely high reliability. Once a vehicle collision occurs, the collision sensor rapidly transmits a signal to the airbag control unit through this terminal wire, and the control unit triggers the airbag to deploy, protecting the lives of the driver and passengers.

In the Electronic Stability Control (ESC) system, terminal wires connect various sensors (such as the lateral acceleration sensor, steering-wheel angle sensor, etc.) to the ESC control module, ensuring that the signals from each sensor are accurately transmitted to the control module. This allows the control module to monitor the vehicle's driving status in real-time. When the vehicle shows a tendency to lose control, the control module can promptly take measures such as braking or adjusting the power output to stabilize the vehicle's driving.

Body Electronics System

Terminal wires connect the door control module to components such as the window motor and door-lock motor, enabling the control of functions such as window lifting and door locking.

Terminal wires are used to connect the vehicle's lighting system, such as the headlights, turn signals, brake lights, etc., to the body control module, controlling the lighting, extinguishing, and flashing of the lights to achieve vehicle illumination and signal indication functions.

In the windshield wiper system, terminal wires connect the wiper motor to the wiper control module. According to the signals from the rain - sensor or the driver's operation, the control signals are transmitted to the wiper motor, enabling the wiper to operate at different speeds and frequencies for windshield cleaning.

Special Applications in New Energy Vehicles

In the battery management system, terminal wires are used to connect the battery pack to the Battery Management Unit (BMU). They need to have extremely high electrical conductivity and corrosion resistance to achieve efficient energy transfer between battery packs and long - term stable operation. At the same time, they transmit information such as the battery's voltage, current, and temperature to the BMU, enabling the BMU to monitor and manage the battery.

The terminal wire connecting the drive motor to the motor controller must be able to withstand high current and high voltage, ensuring the reliability of power transmission and control signal transmission between the drive motor and the motor controller, and achieving precise control of the drive motor to drive the vehicle.

IPv6 network supported

IPv6 network supported